With next year’s car design well underway, Honda had left McLaren high and dry in terms of finding a new power unit partner.

“It was very late in the day – the options were limited,” says Jeffreys. “The fallback position was a Ford customer engine. Ayrton wasn’t keen on staying – but his options were limited too.

“Of course he then did his famous deal with Ron…”

Renault’s power unit was the choice of the grid with around 750-780bhp, whilst Benetton – with the works Ford deal – had roughly 700-730bhp. The customer Ford HBD7 left Woking working with around 680-700bhp.

Senna would eventually agree to drive on a race-by-race basis for McLaren for the eye-watering sum of $1m a GP but, prior to that, the Woking design team had to come up with a car which would persuade the three-time champion to compete.

For 1993, new FIA technical regulations resulted in cars becoming significantly smaller: the ‘track’ (axle width) was reduced from 2150mm (7ft 1in) to 2000mm (6ft 7in), the width of the rear tyres were reduced from 457 mm (18in) to 381mm (15in), and front tyre width from 330mm (13in) to 279mm (11in).

All this was done was to reduce cornering speed in the name of safety. It could be argued that in terms of chassis and aerodynamics, McLaren nailed the new rules better than anyone else – but this didn’t mean the design process was without its challenges.

Tight MP4/8 packing contributed to a nimble F1 car with good handling

Grand Prix Photo

Things were further exacerbated by the raft of technological innovations that McLaren introduced in response to the Williams FW14B – the MP4/8 had active suspension, traction control, a semi-automatic gear box and two-way telemetry.

“Henri Durand was the chief aerodynamicist,” says Jeffreys. “He and his team came up with a fairly challenging packaging requirement for the aero point of view.

“Because the car was pretty small, trying to get everything in was quite a nightmare. It was really a study into the efficiency of packaging design.

“We were using a female chassis mould, which meant we didn’t have much room for the driver, never mind anything else. Because of the active suspension, there were lots of control systems, hydraulics running all over the place, wires and cables running that had to get through from front to back.

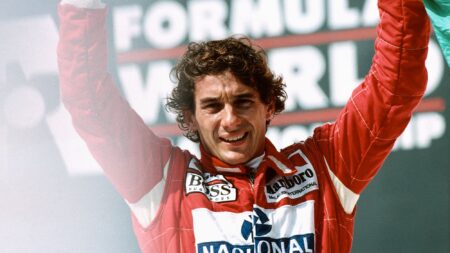

Senna appeared quickly at home in MP4/8

Grand Prix Photo

“It was a challenge to find the space for everything – that’s my main memory of it.”

This created some classic back and forth between different elements of the design team, which was now working with the much smaller Ford V8 compared to the Honda V12.