One of the advantages of working for BRM, says Southgate today, was the huge range of engineering skills available within the parent Owen group. “I had a budget of £25,000 for the 153, but that was purely for things I had to buy in. Anything that could be made in-house was effectively free. If I could have had everything down to the tyres made in-house, the car would have cost nothing.”

Despite the fluid form, Southgate’s light monocoque – weighing 57lb bare – is a straight-sided ‘bathtub’ ending behind the driver. But the V12 was not designed to be a stressed member, so the 153 uses a triangular tubular frame to take some of the suspension loads off the block. This allows the rear suspension to hang off the transmission, with wheel location by a single top arm and a reversed lower wishbone, plus radius arms forward to the monocoque. The front uses a conventional double-wishbone layout, and as if to reinforce BRM’s reputation for the highest engineering quality on the grid, the steering rack and some of the suspension was machined from super-light titanium.

A top outlet to the front-mounted radiator was claimed at the time to provide some measure of downforce on the front axle. “No,” says Southgate. “That car relied on its wings. The top exit was just convenient.”

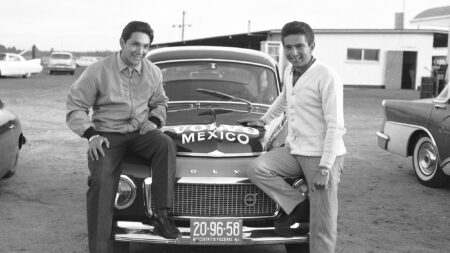

Oliver (left) and Oliver go head to head at Hockenheim

Bernard Cahier / Getty Images

For 153, Woods had to improve the 48-valve V12’s erratic output. Better-breathing heads and improved cooling made the figures healthier, while reversing the heads allowed the exhaust to exit outside with the induction nestling in the centre. Now the pipes could poke discreetly through the rear suspension, cleaning up airflow to the rear wing. The only element which is less than tidy is the twin oil radiator and L-shaped oil tank above the gearbox. These were forced on the designer.

“To keep the V12 so compact – it was only two inches longer than a DFV – they used narrow bearings which frequently failed, putting a rod through the block. We had about 12 engines, and at one race there was only one without a patched crankcase. The only way we could overcome that was to pump huge quantities of oil round, which meant a large oil tank. We got to 4.4 gallons in the end, and we just knocked up a flat-sided job for speed. I made a much neater one for the P160 when I had more time.”