Where and how much?

With tens of thousands of spectators expected at the Festival of Speed, it's vital that you give yourself plenty of time to get to Goodwood Park. From the M25, leave…

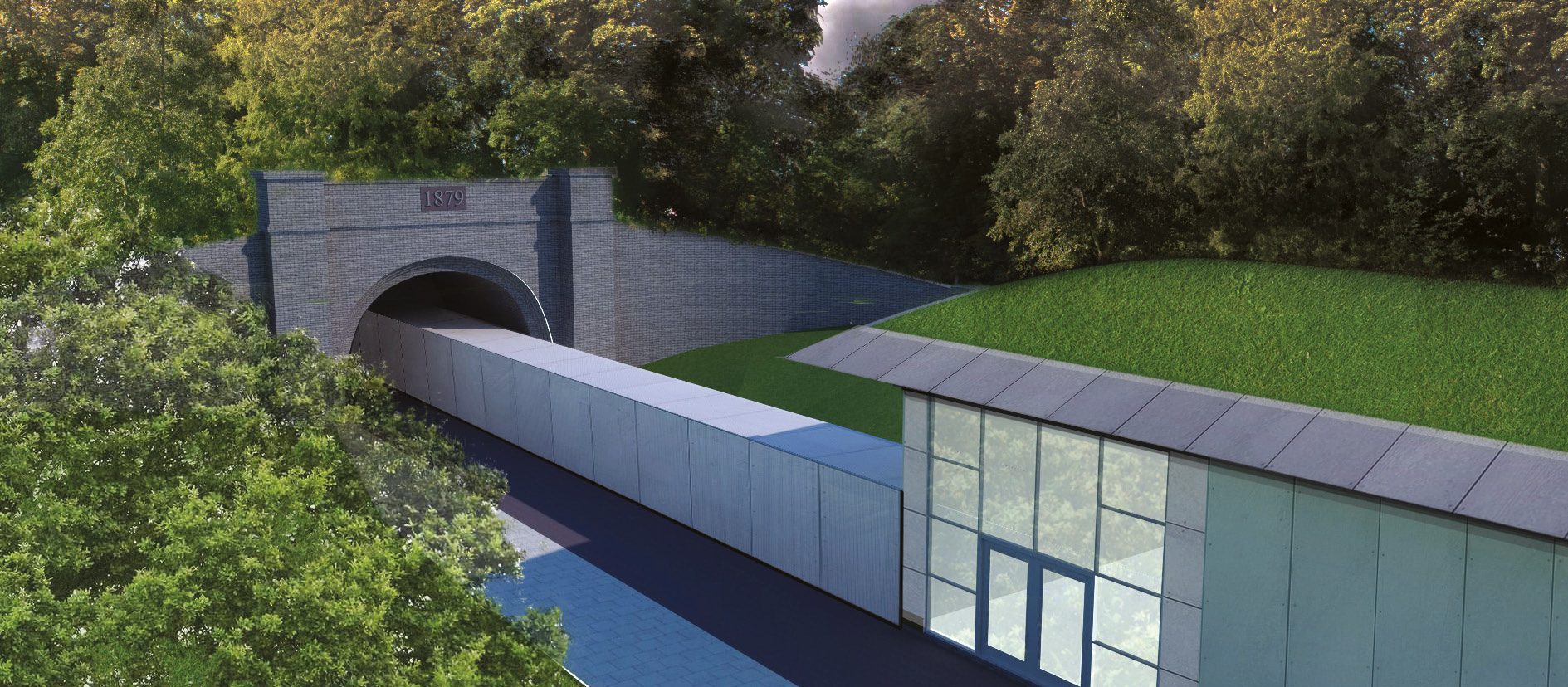

The news that Britain will soon have its own high-speed hole in the ground – a disused Victorian railway tunnel turned into a car test strip – marks the latest step in the assessment of car aerodynamics, a pursuit that began over a century ago.

In this latest development, computational fluid dynamics (CFD) specialist TotalSim is turning the disused Catesby rail tunnel in Northamptonshire into an advanced aero facility. Cars, with drivers aboard, will shoot down the dead straight 1.7-mile tube, accelerating into the centre measurement section, and then have half a mile to stop. Turntables at each end mean a quick return. With no fans to drive, power use and noise are radically reduced. “And the repeatability is rock-solid,” says the firm’s John Paton. “It closes the loop of the three methods. CFD gets better all the time but it’s not the real world – there’s no vibration or heat for example. The tunnel will allow us to validate model tests and CFD against the real thing. It’s the perfect companion.”

It also completes a loop back to the roots of the technology, when wind tunnel testing was just as contentious as today – not due to environmental concerns or F1 testing limits, but because many didn’t believe that blowing air over a static car had the same effect as driving in free air. It took the genius of bridge designer Gustave Eiffel to prove it did – and that’s just the same debate that today’s wonder tool CFD had to win before being accepted into the aerodynamics armoury.

Not surprisingly it was dreams of flight that produced the earliest tunnel, in 1871. But while some pioneers, notably the Wright brothers, learned much from tunnels it was not very relevant to early road cars. Record cars were different – 100mph was breached by 1904 – and some of these featured tapered, wedge or torpedo bodies. But there was little comparative testing; they just looked fast. Until Peugeot contacted Eiffel.

Tunnels were rare at the start of the 20th century – doubters preferred tests where the air stayed still and the test piece moved, fixed to a car or a train, swinging round on an arm, or sliding down a zip wire. Even tunnel pioneer Eiffel tried dropping objects from his famous tower to check drag before in 1909 building his first tunnel at the foot of his landmark – a seminal event in aerodynamics.

He wasn’t the first; experimenters had blown or sucked air over objects before this, but Eiffel hit on the shape we still use – the venturi with its narrowing and then opening throat. More importantly, he realised his device could test model buildings, planes, trains – and automobiles.

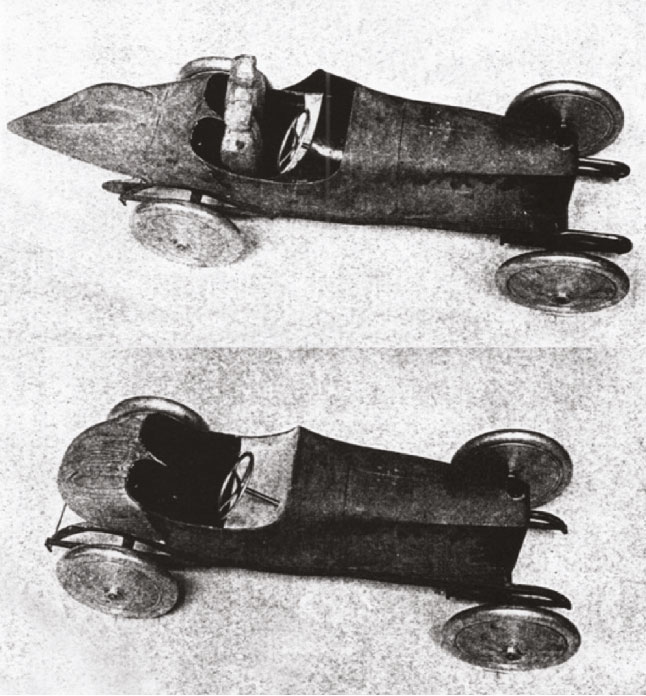

Previously it had been about speed, but in 1913 the ACF reimposed fuel consumption limits for its grand prix, and a year later a 4.5-litre capacity ceiling. Drag factors had a new relevance, so in 1914 Peugeot sent models of its L45 racer to Eiffel’s tunnel. The result was that the Peugeots arrived at the Lyons Grand Prix with tapered tails, full undertrays and smooth front edges. They didn’t win, and it didn’t change racing car design overnight. But it proved that model testing worked, that results were repeatable and controllable. Once engineers worked out how to scale model results compared to full size, a new field had opened up.

Quickly crucial in aircraft design, aerodynamics still had limited application to wheeled vehicles. Even racing focused on power and handling, and a limited amount on frontal area, but few had even heard of drag coefficients. Once racing cars went single-seater, racing bodies began to look smooth and sleek but more by received wisdom than empirical testing. And the wisdom was – streamlining. As cars and aeroplanes fought over speed records the word quickly caught the public mood as shorthand for advanced, futuristic, stylish. And it came from the wind tunnel.

Once your car is installed in a tunnel you need to make some measurements. Balance bars and spring balances can check drag and lift, but to improve profiles engineers needed to ‘see’ the air flowing over their careful curves. One method was to apply a chalk and oil mix which dries off to show useful patterns. Another answer was smoke, fed to a series of nozzles so lines of it streamed over the test item – the ‘stream lines’ that would shape the Art Deco era, from planes to washing machines.

Such a look was easy to apply to a car: smooth noses and tapering tails echoing aircraft forms became the racing norm. Fiat’s vertical-ended ‘Bordino’ tail on its 1922 GP cars came from the firm’s aeronautical department, but through the 1920s few cars reached tunnels and without proper testing the importance of the small elements – louvres, lights, hinges – slipped by. Few wind tunnels could yet take a complete car and making a test model wasn’t on anyone’s radar. There were open-air options: coast-down – timing how long a car takes to slow from a given speed – was and remains a valuable tool, while tufts of wool glued to the body or a hand-held wand look comical but yield useful clues about surface airflow. What you couldn’t measure was internal flow, such as cooling, and how lift affected stability – a vital element no-one was yet looking at.

Pioneer aircraft designer Edmund Rumpler tried to reshape the car scientifically in Germany’s aviation tunnels, leading to the 1923 Benz Tropfenwagen racing car and hints at the later A-type Auto Union. After shaping airships in the Zeppelin tunnel, Austrian Paul Jaray transferred his knowledge to cars from the Twenties on, which trickled into a few racing designs. Adler tested very efficient Jaray-style Trumpf coupés using wool tufts before they ran at Le Mans in 1937 and ’38. It was proof that low drag compensated for low power – on just 56bhp they finished seventh in ’38. But Jaray’s tapering tails and narrow cabins made for an inconvenient package. Tunnel testing produced ideal forms, but this isn’t an ideal world.

Jaray had shown that car shapes could be scientifically tested, but the simple ‘what looks right, is right’ principle dominated. As fashions go, streamlining worked better than most – tapering forms and cowled radiators intuitively give cleaner aero – but there was little awareness that those surface details mattered more than a long tail. In any case, on a racing car, enclosed fairings made the mechanic’s job difficult, and extra bodywork weighed more. Fashion and aesthetics produced some smooth shapes – George Paulin’s Peugeots and Bentleys, Bugatti’s T57 Tank – but aerodynamics remained a fringe aspect for most makers.

One exception was Daimler-Benz. Aero studies for its 1920s Indianapolis racers showed promise, and in 1932 Manfred von Brauchitsch took a victory at AVUS in a streamlined Mercedes SSKL. Smoothly faired shapes appeared on the 500K and 540K Autobahnkuriers and a coupé for the cancelled 1938 Berlin-Rome race, and also its grand prix cars: from 1934 the company combined coast-down runs with model testing in a small tunnel at the Stuttgart Technical Institute, replaced in 1939 with a facility that accepted full-sized cars. (Radically updated, this FKFS facility is still a vital cog in Daimler-Benz engineering today.)

Hence the clean lines of Stuttgart’s racers from the lean W25 to the radical streamliners of the late Thirties which contested speed records with Auto Union on the Darmstadt autobahn – with fatal results. Auto Union’s engineers knew their hastily modified streamliner showed instability in the tunnel but as 1938 dawned a frenzy of rivalry between the silver marques meant there was no time to adjust. At 269mph a sudden side gust pushed even the skills of Bernd Rosemeyer beyond critical; he died at the scene. Gaining the knowledge is step one; step two is applying it.

Key man at the Stuttgart institute was Prof Wunibald Kamm, an aero genius who would give his name to a vital lesson: his tunnel tests showed that if you chopped off that pointed tail at the right place a cone of still air filled it in for you. Result: the Kamm tail – a shorter body retaining good drag, a lesson BMW employed on its 1939 328 coupés which beat bigger cars on the 1940 Mille Miglia. Alfa Romeo’s high-tailed 2900B which led at Le Mans in 1938 and the little Fiat 508MM show the same influence.

Post-war it was another aircraft engineer who brought slippery elegance to the race track. Malcolm Sayer’s C- and D-type Jaguars slid through the air at 180mph, shaped by calculation, experience and open-air testing – prophetically, he doubted tunnel figures because of the static wheels. Nevertheless a trip to the Royal Aircraft Establishment at Farnborough, which had increasingly larger tunnels from 1906, to place a D in front of the 30ft fan of its biggest – able to swallow entire aeroplanes – confirmed his work. Benetton would later use the same historic facility, now a listed building. Only in 1960 did the UK get its first full-size car-dedicated tunnel, at MIRA, although as it measured only drag it was less suitable for racing; it was model facilities at universities such as Southampton and London’s Imperial College which would prove crucial in race car development.

As the maths and the measurements meshed, it became possible to calculate and predict aero behaviour: aerodynamicist Frank Costin stated his sleek 1956 Vanwall was shaped by slide rule and never saw a tunnel until later. Costin’s work for Lotus led the way in sleek designs from the MkVIII on: his brother Mike, then Colin Chapman’s No2 at Lotus, recalls him strapped to a speeding car on an airfield observing the wool tufts. Chapman seized the baton with the pencil-shaped 21 to 33 single-seaters, aiming at good penetration with plenty of airflow beneath but not tunnel-tested, although Lotus trialled windscreens on the 29 Indy car in MIRA’s tunnel in 1963.

Now it was sports cars with their full-width bodies which highlighted an increasing threat – high-speed uplift, destabilising and sometimes catastrophic. Techniques to cancel lift and restore stability came by experiment, especially among American Indy and sports car teams where strips of metal – the Gurney flap – and nose winglets cut lap times – but no-one knew exactly how. It would take tunnel testing to show why, and in the UK that meant going to the universities.

Tony Southgate worked on the Lola T70 in the mid Sixties and says that while they knew spoilers made the car faster, they didn’t know why. He took a model to City University in London where one expert was developing the ‘perfect’ car body. After testing Tony’s model he threw up his hands: “You’ve ruined my life’s work!” The ‘spoilered’ model clashed with pure theory but worked better. Stability, traction and increased tyre grip counted for more than drag, especially with a powerful V8 pushing the car through reluctant air. Now as racing car designers tried to stop the air flowing under the car and kill those dangerous low-pressure areas that could lift the tail, a new horizon appeared. Downforce.

All this Ford was discovering in the US in the early Sixties, using the corporation’s extensive tunnel facilities to shape the GT40, though Southgate remembers often seeing GT40 models at City: “The aero was awful – they had a new nose every week until they finally got it right”.

But there was a smaller team with below-the-pit-counter access to a major tunnel: Jim Hall’s Chaparral outfit. While its links to GM’s vast aero facilities stayed below the radar, the innovations were visible as flips, ducts and spoilers marked Chaparral’s inventive aero development towards the next breakthrough.

“The GT40 aero was awful – they had a new nose every week”

We’d seen wings before on record cars and the odd Porsche, and in 1952 Stirling Moss discovered his Mercedes 300SLR air brake also increased cornering power, but once that aerofoil flew above the 1966 Chaparral 2E, everyone wanted some of this free gift. That led Formula 1 toward the ill-fated strutted aerofoils of 1968/69 – acting direct on the tyres and raised high to clear the messy body-surface air tunnel testing had revealed. A perfect equation that multiplied grip with speed – and calamity if a strut broke.

With these banned and fixed body-mounted foils mandated, Chapman’s Lotus 72 wedge supplanted a winged 49, indicating the next approach with nose and tail wings which could be changed and tweaked.

After 70 years drag had become a force for good. And measurable – as long as you could book tunnel time at MIRA, Imperial, Cranfield or Southampton Universities. And keep it quiet: Lotus designer Martin Ogilvie recalls that for secrecy only the Imperial technician was allowed to work with them.

Peter Wright, who was instrumental in developing ground effect, had earlier side-stepped this bottleneck, building a ¼-scale tunnel (powered by a VW engine!) for bodywork maker Specialised Mouldings. John Barnard shaped the Can-Am Lola T260 there. “They sold it to Williams, who later passed it on to Lotus,” Wright says. That’s how prized wind tunnels were.

For McLaren’s M23, John Barnard found a tunnel on the Isle of Wight. “It was used for Concorde work – and hovercraft,” he recalls. This was some of the very first full-size aero testing. “We developed the single-post wing there. Then at Parnelli we took complete cars to Lockheed’s 200mph tunnel in Atlanta – very expensive!”

There was still a snag in tunnel testing: a fixed floor didn’t equate to passing over the track at speed. Spinning the tyres improved the equation, but it wasn’t until 1975 that Imperial perfected a moving ground tunnel, a huge belt under the car that spun the wheels at road speed. Tunnel testing was closing in on real life. “Everyone and his dog wanted to get in there – the moving floor was vital,” says Southgate. “We found a 15 per cent difference between fixed and moving floors. One of the worst cases was Porsche’s 956 – it was developed with fixed wheels and floor. On the XJR-14 we had very sophisticated models and found we had far more downforce than a 962.” Indeed, Porsche had struggled with aero problems from the 907 onward, employing the French SERA institute to parallel work at FKFS.

A moving floor creates immense friction and consequent cooling demands, but it was vital. It was at Imperial that Peter Wright’s team made the momentous 1976 step into ground effect – the ‘something for nothing’ prize that pitched racing aero into a new era. It could not have been pinned down and quantified without a tunnel. (Although it was noted before that – Donald Campbell’s Bluebirds gained some downforce from underbody mods in the Imperial tunnel.)

Wright had posited an upside-down wing for BRM in the late ’60s and with the Lotus 78 was aiming for a simple wing car, but when the moving belt lifted and the sidepod sagged he and designer Ralph Bellamy could suddenly see suction in action, a discovery that would lift racing into a new age.

Now a wind tunnel was crucial, increasing pressure on proprietary facilities. Back at McLaren, Barnard found a tunnel at the National Maritime Institute where the team installed its own moving floor, using it into the 1980s. Arrows went to the Royal Aircraft Establishment at Bedford; Ferrari relied on Pininfarina’s facility or Airbus at Filton, and even aerospace company Matra came to Imperial to use the moving-ground tunnel for cars, while Penske used Southampton for its Indy-winning PC23. It was the 1980s before F1 teams built their own, starting with Gordon Murray’s (typically self-designed) unit for Brabham in 1981. “That was the big investment Lotus never made!” smiles Wright.

“A wind tunnel was the big investment that Lotus never made!”

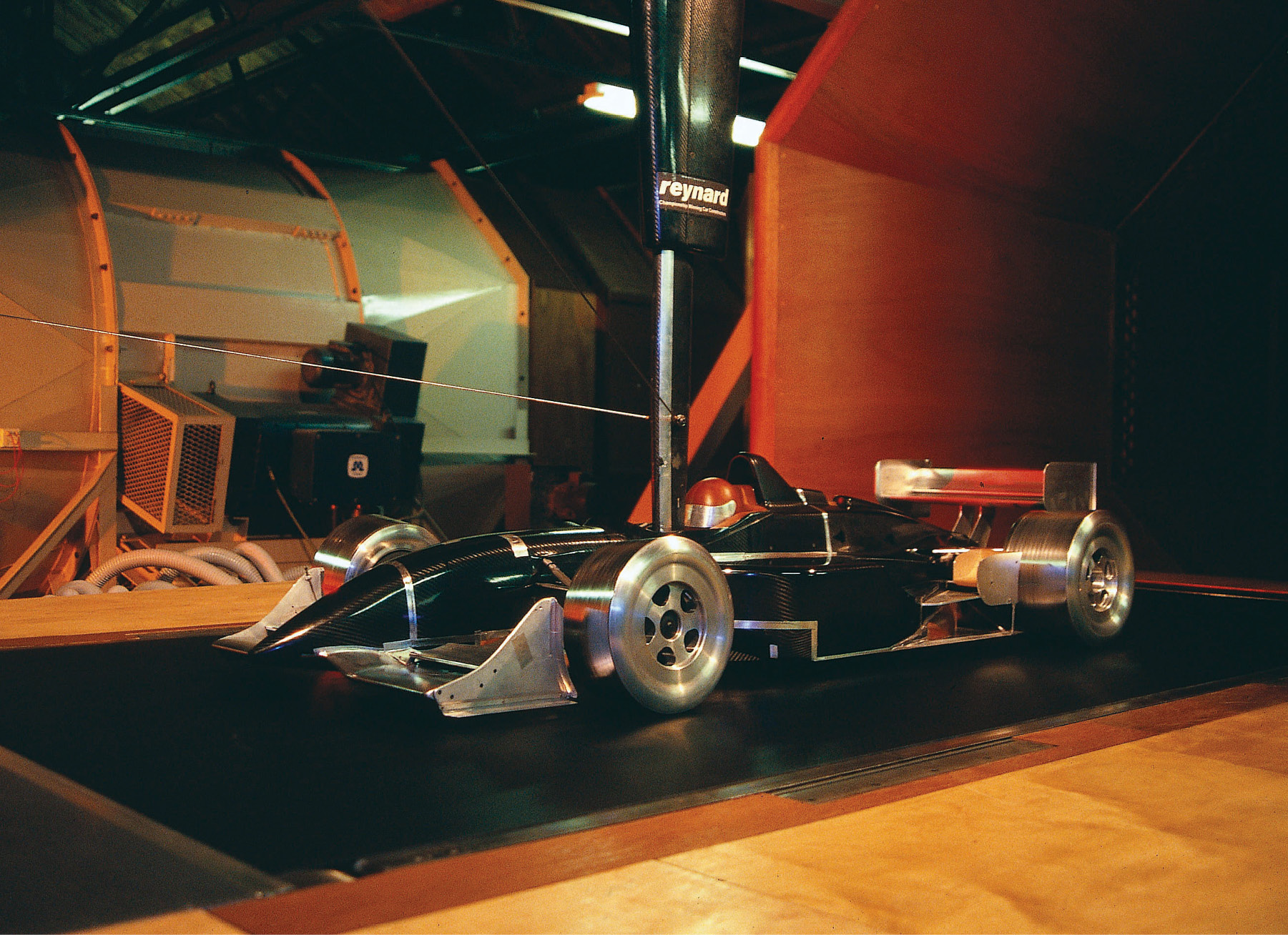

Now most F1 teams have their own wind tunnel, sometimes two, which until limits were imposed worked flat-out all year. Other teams rely on universities or commercial operations such as Windshear in the US. Model scale is limited to 60 per cent, beautifully and expensively crafted in intricate detail. Once they would be hand-carved in wood, then in slow and costly carbon-fibre – “more expensive than a real car,” says Southgate. “I saw one that cost $1m!” Today they are 3D-printed direct from the CAD model. Moving floors are a given; turntables give crosswind and yaw figures, multiple miniature transducers monitor pressures while laser and other particle visualisation techniques show distribution, vortices and above all that precious downforce. But it’s hugely expensive, noisy and power-sapping – and very un-green. It’s a long way from tufts of wool on a runway.

Yet this is only half the story. From the 1980s the surge in computer power assisted the arrival of CFD, the number-crunching method to virtually visualise moving air. Its accuracy has soared over the years, meaning it can usefully feed back to physical tunnels. Superb as today’s tunnels are, there are always flow and drag effects which would be absent in free air. Now by comparing tunnel figures and pure CFD of the same object, tunnel results can be digitally adjusted to represent free air, minimising the inherent errors of even the finest tunnel.

And now we’re returning to historical technique of a moving car in still air. In the US the Ganassi team began exploiting the disused Laurel Hill rail tunnel in 2004 and it is now block-booked by one manufacturer. TotalSim hopes that Britain’s equivalent at Catesby will be running by 2021.

Today’s F1 designers can prove that those tiny winglets on a front aerofoil are worth a hundredth or two, and they know it so precisely because the three main ways of checking – physical testing, wind tunnels and CFD – are collectively homing in on the ‘true’ picture. This cross-referencing is exactly what Gustave Eiffel had to do to prove that his new-fangled wind tunnel gave the same results as his drop tests. That’s the scientific method in action.