Car models on a different scale: How Amalgam creates its small wonders

Almost as intricate as the cars on which they’re based, Amalgam’s scale models take accuracy to lofty levels. Cambridge Kisby visits the Bristol base to find out how it’s done

Jonathan Bushell

Buried within a relatively small industrial estate in Bristol lies a workshop like few others. Replacing the potent smell of motor oil and the deafening whirl of heavy machinery is the occasional rustle of masking tape, as steady hands labour over some of motor sport’s most legendary machines. In one corner sits Red Bull’s record-breaking RB19, the exact chassis driven by Max Verstappen to victory at the 2023 Dutch Grand Prix. In another, parked side-by-side, are two icons of the Le Mans 24 Hours: the 1969 Ford GT40 in which Jacky Ickx and Jackie Oliver claimed the American motor giant’s last top-class success at La Sarthe; and Sir Henry ‘Tim’ Birkin’s 1929 Bentley Blower.

Jonathan Bushell

Graham Hill’s ’68 Lotus, 1:8 scale

Jonathan Bushell

Take a seat.

Jonathan Bushell

But lurking at the very back of the workshop is perhaps the most eye-catching attraction – Ludovico Scarfiotti and Michael Parkes’ Ferrari 330 P4, as driven at Le Mans in 1967 to second-place honours. It’s a flawless example, and the best news is, just like all the others, it would fit perfectly on the desk at home — given that it is 21in long.

“Computer-generated 3D scans of the car are sent to the modellers”

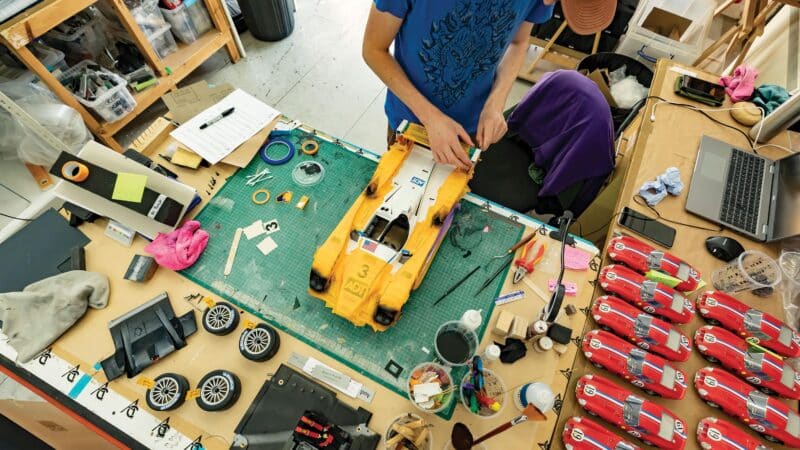

Welcome to the Amalgam model workshop, a place where for almost 40 years craftsmen have been recreating in intricate detail some of the most famous racing cars in motor sport history. The resulting models are prized for their period accuracy and faithful reproduction – including every blemish and upgrade.

Take the Ferrari 330 P4. It is being worked on by Kallon Jaye Rawlings, one of five artisans entrusted with the work, who is diligently applying a layer of paint with a tiny brush. “I’m starting to weather it,” he says as he stares intently at a picture taken of the Ferrari at La Sarthe in 1967 — before applying an intricate streak of muddied paint just to the left of the rear wheel. “We want it to look as if it’s just pulled into the pitlane, 50 years or so after it actually did.”

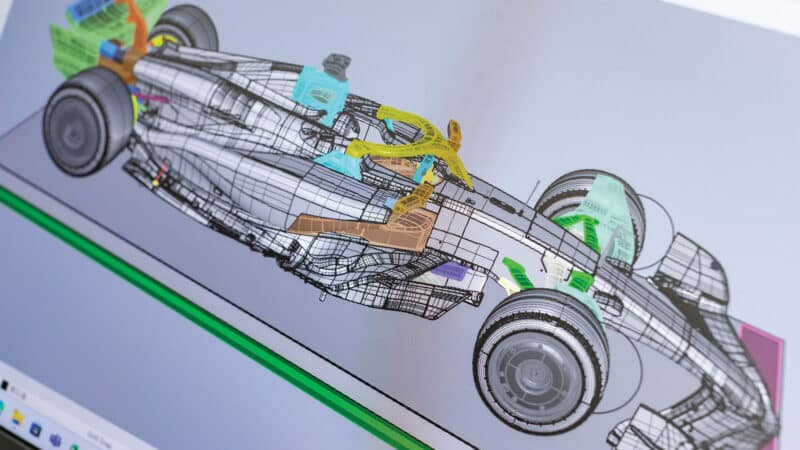

Confidential CAD data is used in Amalgam’s F1 models.

Jonathan Bushell

A Red Bull for your desk?

Jonathan Bushell

Amalgam has had an association with Ferrari since 1998.

Jonathan Bushell

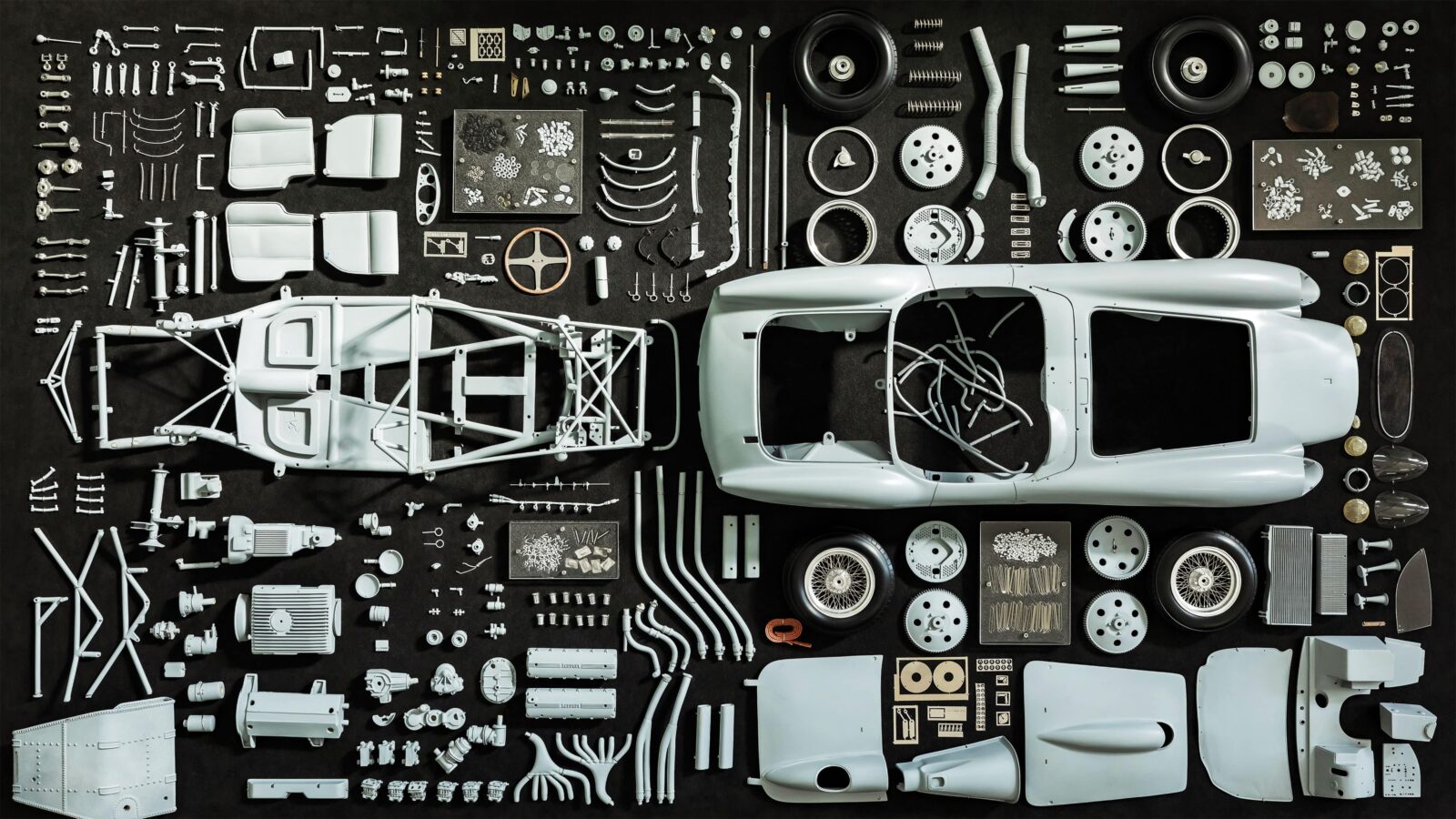

The company has seen a gradual increase in demand since 2020 — coinciding with the boom in motor sport popularity — and its products are ordered and enjoyed by star-studded clients which includes the likes of Charles Leclerc, Rowan Atkinson, Sylvester Stallone and Gordon Ramsay. Each model, which can contain anywhere between 400 to 2000 precision-made pieces depending on its size and intricacy, often begins life in the factory of the original manufacturer. Computer-generated 3D scans of the original car, which contain every nut, bolt and screw used to hold it together, are sent directly to the modellers at Amalgam, who, over 4500 hours, develop and shrink the model to scale, before generating castable pieces with a meticulous level of detail.

After parts are shipped from factories in China and Hungary, the model then takes a further 450 hours to assemble and weather, as details are added to fully capture the spirit and precise appearance of each one: from the dirty handprint of an engineer on the bonnet of Ickx’s GT40 to a bent wheel guard on Birkin’s Bentley.

Birkin’s Bentley in 1:8 scale, looking like it’s been racing at La Sarthe for a full day

Jonathan Bushell

Never underestimate the commitment to historical accuracy in motor racing circles, as Amalgam modeller Toby Moir explains: “We’ll usually work from a single ‘hero image’ of the car at a specific race or point in time. From that, we’ll extract as much information as we can to replicate those details on the model.

“We can also get information and specifics straight from the client. We had one order from an engineer a few years back who worked on one of Porsche’s Le Mans-winning 917s. He sent us a whole load of engineer’s drawings and specifics which he wanted included, like how many wing nuts there were on the bonnet and the angle they were facing.

“He also asked us to bend the ignition key, as he specifically remembered it in that condition when the team pulled the car back into the pitlane.”

All this supreme attention to correctness comes at a price: 1:8-scale models start at a base price of £8495 for Ferrari’s Australian Grand Prix-winning SF-24, driven by Carlos Sainz in 2024, but can climb above £20,000 for, say, a Le Mans 2006 Aston Martin DBR9 or 2009 Aston LMP1.

Each car can take two years to develop

Jonathan Bushell

Pro model maker Jules Rinterknecht

On request, Amalgam can also build a bespoke version of your own car — an option which has grown in popularity with numerous F1 teams as well as motor sport-enthused celebrities.

“We began as a general model-making company back in 1985,” recalls Amalgam founder Sandy Copeman, “but as we grew, I thought it would be cool to try and work with Formula 1 teams.”

After an initial meeting with Tyrrell in its famed wooden shed, Amalgam secured its first official licensing deal with Jordan and produced models of the 195 and the 196, before striking up a similar agreement with Williams during its world title-winning years in 1996 and 1997. But with sales still minimal, Copeman saw no other option but to target the biggest name on the market. A trip to Maranello was in order.

Weathered perfection on a GT40

Jonathan Bushell

Le Mans dirt on your GT40?

Jonathan Bushell

“We approached Ferrari in 1998, and we were taken on almost immediately,” he recalls. “They loved the fact we had worked with such high-level architects and, of course, soon after we got one model out of the 1998 car, the 1999 car won the constructors’ championship and then everything took off for us with Michael Schumacher in 2000. Suddenly we were selling reasonable quantities of 1:8-scale models [which at the time cost around £2800], and that was a big turnaround.

“As we grew I thought it would be cool to try and work with F1 teams”

“Our relationship with Ferrari has continued to this day and remains key. They were also the first team to supply us with official CAD [computer aided design] 3D data straight from the factory. It had been tampered with in order to avoid giving any secrets away, but that not only improved the details on the models but also helped build up our trust with other racing teams, who could look and say, ‘Well, if Ferrari is giving away its data, it’s probably safe for us to do so too.’”

From there, relationships blossomed with McLaren and later Red Bull, who at one stage were impressed to the point of suspicion as models of the RB9 were so detailed that engineers thought data was being leaked from the factory.

Company founder Sandy Copeman. Above: take a seat.

Jonathan Bushell

As well as manufacturers, Amalgam also caters for genuine collectors of motor-sport history. George Lucas, the creator of the Star Wars and Indiana Jones film franchises, is the first name that comes to mind when Copeman is asked about some of his favourite Amalgam models to date.

“George worked as a mechanic and crew chief for Shelby back in the 1960s,” he says. “But before he made all his film-making money, the original Cobra he worked on – apparently he designed its livery – was sold off in an auction. So George gave us a call and asked us to make him a model of it, supplying us with loads of photos as well as personal accounts of what Allen Grant [its driver] did to it while out on track. It was really very special.”