The car featured sponsors between the wheels, with a stressed sheet floor and bulkheads in mag nesium. The front bulkhead was double-skinned, effectively forming a box in which the front differential was housed. Its DFV was fitted back to front so that the clutch was immediately behind the driver’s seat, and the output shafts to and from the centre duff were sited to the right of the car, the driver being offset to the left to make way.

It was a striking-looking machine, and it would be interesting to compare Cd figures with other cars. I bet there’d be a few surprises. Herd’s background was in applied mathematics and aerodynamics, so I’m sure it was more considered than most designs of the day. It never struck me as being a slippery shape, more as an efficient body designed to be produced very quickly in terms of tooling and pattern-making. It’s clear the car was built as a one-off. If you make a glassfibre nosecone, you must first form a wooden buck, then create the mould from that.

This takes up 90% of the whole process of producing the item. On the Cosworth, someone simply spent time folding aluminium sheet. It would have taken some drawings, but not much else.

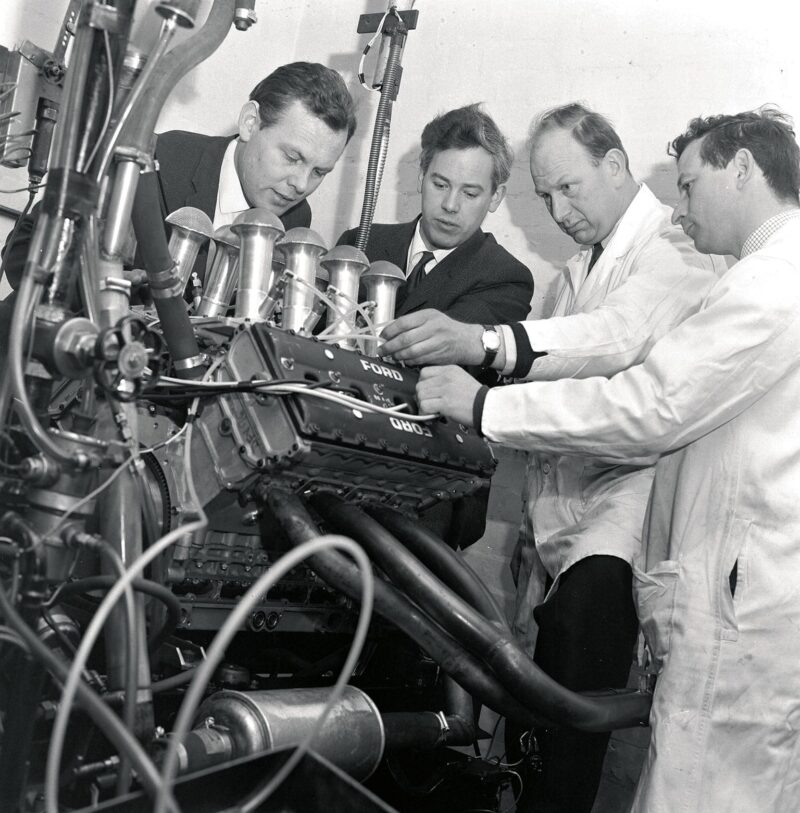

Front-end structure of the Cosworth 4wd car

Grand Prix Photo

But there was something that caught my eye more than the car’s radical shape: its bare aluminium. There’s something about this material that really grabs my imagination. It’s lovely to work with, easy to file and shape, and you can get a beautiful finish on it. A little wire wool, moistened with paraffin, a few wipes, and there’s a shine that catches the light like no other. The glint from the thread when you remove a tap from a casting is something that fires dreams for some people.

Yes, yes, you say, but what about the reality? How did the car go? Not great.

On paper, it was a purist’s dream: same suspension geometry front and rear; same tyre sizes front and rear; a 50:50 weight split; no bolt-on aerodynamic aids. On the track, though, it was a driver’s nightmare. When you look at photographs of it being tested during the spring of 1969, there are a lot of grumpy faces. Apparently, the big problem was imbalanced traction through the front wheels. The car weaved alarmingly, even on the straights. This was probably due to the limited-slip action of the front differential.